Custom Camera Design for Medical Devices

As technology continues to advance, vision plays a significant role by improving the diagnostic process with real-time feedback for the operator. Building a camera for use in a medical system can seem daunting. The right vision partner will help navigate the engineering process, refine functionality and facilitate integration. We will review the process of designing a custom camera for medical devices: considerations, expectations and steps to follow.

Manufacturers of medical devices have to consider numerous factors when incorporating vision in to their diagnostic equipment. This overview of the custom camera design process, from image sensor selection to prototype validation and final approvals. An expert in custom camera development can help the medical team navigate these decisions and provide a quality product that conforms to the necessary regulations.

Choosing the Right Sensor

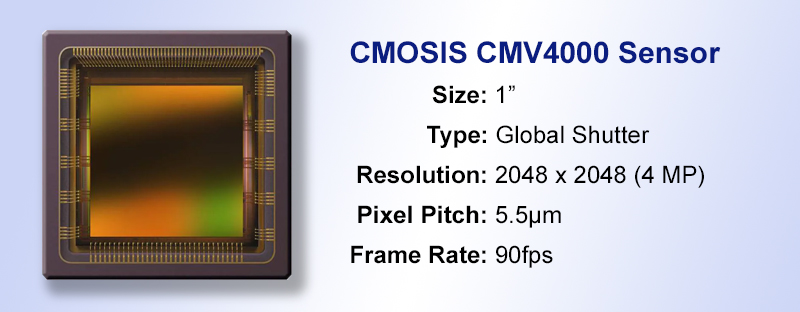

The first step in designing a custom camera is identifying the requirements for the vision system and selecting the correct sensor. The primary characteristics of a sensor will be resolution, pixel pitch, field of view. How many megapixels the sensor will produce and the size of the pixel will determine the field of view or imaging area. The type of image needed with determine the pixel size. Smaller pixels will provide finer detail while larger pixels will produce higher signal-to-noise ratios (SNR)Image quality will be determined by the cameras intended use. Will the image be for visual feedback and documentation or will the data itself be used for diagnosis. Diagnosis will likely require higher quality images to ensure accurate analysis. Spectral range is also very important. The process may utilize visible light, near-infrared (NIR) region of the electromagnetic spectrum.

Determining if there will be movement in the image frame and cost constraints will determine if the type of frame that is needed. A global shutter sensor can capture moving objects without blurring, but at a much higher cost. A rolling shutter is much less expensive but is suitable where there is no movement. The sensor is a significant component and will likely dictate many of the other components.

Sensor Examples

Mechanical Considerations

After choosing a sensor, there are various mechanical considerations. Spatial constraints might limit the size of the camera. Cameras can also generate significant amounts of heat and determining how to dissipate the heat could require some engineering, especially if there is limited space for the camera. Excess heat could impact the sensor function and compromise other components in close proximity.

Choosing the Right Interface

Frame rate can vary significantly between sensors and the interface might vary based on the necessary throughput requirements. The interface sends image data to the host system. If images are captured infrequently, low frame rates are suitable. The data transfer only has to be fast enough to not impact onscreen viewing without lag. 30 frames per second is sufficient.

One of the more commonly used interfaces is USB3 since it is often available with many computer systems and easier to integrate. 10 Gigabit Ethernet can provide greater data transfer speeds in addition to longer working distances. In some applications the host computer might not be in close proximity to the camera eliminating USB3 as an option even if the required data transfer rates are low.

Experience with Medical Approval Process

It’s very important to work with a vision partner that has experience with medical devices. Understanding the process and a familiarity with the requirements will help avoid costly interruptions to the process. Regulatory approvals will be required, both for the entire medical system, as well as for the camera itself. Some approvals are met during the design stage, some during the fabrication of the camera, and some after final system integration. Approval requirements can vary based on patient proximity, power source used and use cases for the device. Navigating these requirements requires can greatly impact the project timeline.

Some regulatory approvals may include:

- FCC/CE compliance for electromagnetic interference

- ISO 13485 for traceability of the product and its components

- IEC 60601 for medical electrical equipment requirement for basic safety

- IEC 62368 for system component safety (to include the camera)

- FDA approvals

Budget Considerations

It will be important to prepare a budget for the design phase of the process. When creating a custom camera, the process is more involved than just swapping out different components. Compatibility and performance have to be evaluated and quality testing has to be performed, especially if it will require FCC, IEC or FDA approvals.

Once the requirements and budget are established, the vision system partner provides a written proposal for the custom camera development project. This would include: Statement of Work (SOW), Costs (NRE and per-camera), and project timeline.

Here are some examples of customization that was required for medical devices:

- Custom firmware/FPGA

- Implementation of customer’s application specific functions in the FPGA, Firmware or host drivers

- Special customer’s entry in camera flash

- Multi-camera synchronization

- IR filter or clear glass removal or replacement

- Cover glass, sensor glass and micro-lens removal

- Custom sensor board mechanicals

- Mount removal or custom designed

- GPIO/Trigger customization to customer’s requirements

- Custom sensor-lens integration and alignment

- Custom sensor calibrations for different specifications or environments

- Custom I/O and connector interfaces

- Remote sensor with custom length and design of flat flex cables

Custom camera development for medical devices can easily be achieved with the support of an experienced vision partner. Software, firmware, mechanical design and project management are all important aspects to the custom camera development process.

Explore the process further for your Custom Camera Development needs.